What is a Drill Collar?

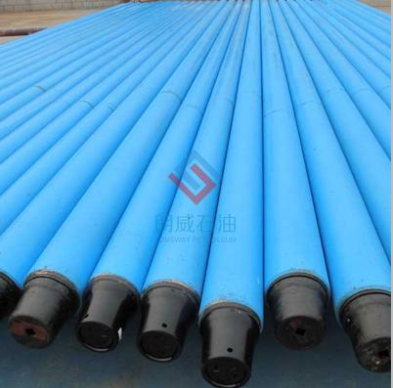

A drill collar is a device used in the drilling of oil wells for weighting the drill bit, enabling it to drill through rock. It is a bar made of solid steel, either plain carbon steel or a non-magnetic steel alloy, drilled lengthwise to permit the passage of drilling fluids. A drill collar forms the lowest element of a drill string, which encompasses all the elements of a down-hole process from the surface to the rock bit.

These devices are typically 31 feet (about 9.45 m) long and threaded at both ends, male at one end and female at the other, to allow multiple drill collars to be joined above the bit assembly. The number of drill collars attached to a drill string will depend upon the material composition of the strata at the drill site and the likely depth of the well. A relatively shallow well with less dense geologic structure through which the bit must pass will require fewer drill collars than a deep shaft through dense material.

Typically, drill collars will be consistent in length but may vary in diameter, and their outside configuration may be slick or spiral. The outside diameter may vary from about 3 inches (7.62 cm) to 11 inches (27.9 cm) and greater. The reference to slick or spiral outer configuration refers to the machining of the outside surface of the collar.

A slick surface simply refers to a collar machined to a uniform cylindrical shape. A spiral collar is machined to have a helical pattern incised into its outer surface. The purpose of the helical grooves is to permit the passage of debris up the drill string and prevent its becoming stuck in the well hole.

The pressure applied to the drill bit assembly by the collar and other elements of the drill string must be carefully regulated for effective drilling. The weight of the drill string is monitored at the surface, and the operator slowly lowers the drill string into the hole until the registered weight changes. If the bit is resting on the bottom of the hole and the monitor shows a reduction of 10,000 pounds (4,540 kg), there should be a corresponding increase in pressure on the drill bit assembly.

Equipment used in conjunction with drill collars in oil well drilling includes drill collar slips, drill collar clamps, and die collars. The drill collar slip is a device used to handle drill collars while attaching new sections, and is adjustable to a variety of diameters. Drill collar clamps are also used while handling drill collars to prevent their being dropped into a well shaft. In the event a drill string is broken and a drill collar and bit are at the bottom of the shaft, the die collar is lowered and with a self-tapping bit, threads an attaching connection into the drill collar, allowing its retrieval.

评论

发表评论